iWePro – Intelligent Self-Organizing Job Shop Production

Today, typical production lines for mass production are primarily designed for specific components and often require rigidly interlinked machining processes. Yet, with increasing product variety, such line-oriented production systems are reaching their limits, failing to quickly respond to changing demands, lacking the ability to meet modified delivery deadlines or quantities.

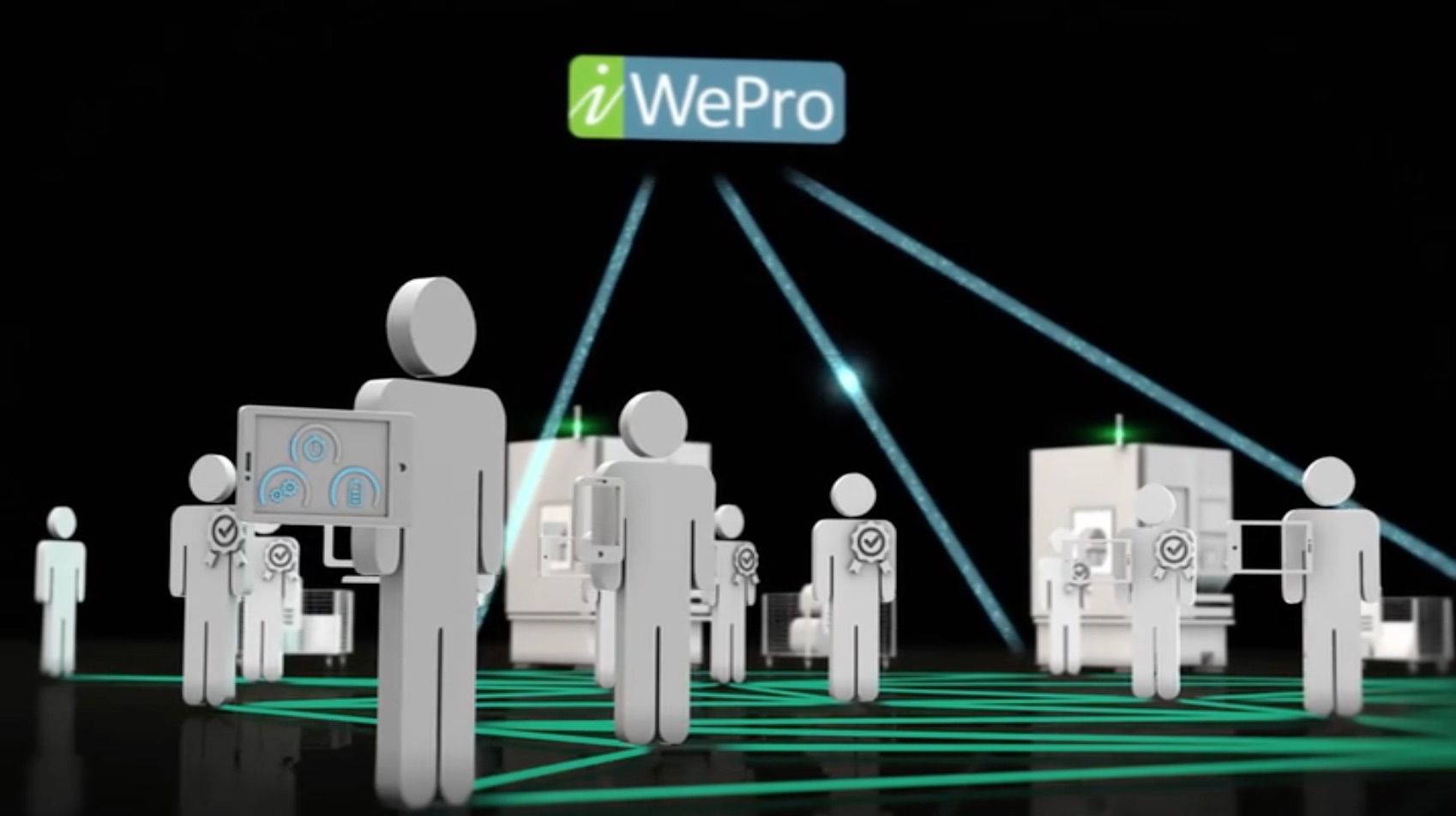

In the »iWePro – Intelligent Self-Organizing Job Shop Production« project, flexis AG partners with experts from science and industry to design innovative production concepts and enable smart job shop manufacturing with decentralized production control.

Job Shop Scheduling

Job Shop Scheduling includes the convenient creation of orders, the mapping of the associated machine-, employee-, material- and tool-structure and the optimization of the process flow for each job, taking into account the complex resource layout of an enterprise. With the Job Shop Scheduling flexis offers a mission-critical instrument / system that combines the advantages of optimized program planning with the benefits of a comfortable and scenario enabled solution for master data maintenance.

The goal of short-term planning in job shop production is the optimization of orders flowing through a complex production environment. In particular in small and medium-sized enterprises, this planning is based on resource allocation with the help of Gantt Charts. So far this process is often done manually or in MS Excel. Inquiries by Sales about feasibility and delivery date for additional orders are often answered only based on experience.

The flexis Job Shop Scheduling goes one step further: customer inquiries are created in the system just like real orders and scheduled on the real resource structure with the given workload.